Green, On-Demand, Abundant Energy by 2050 is Definitely Possible: Here's the Plan

I have discovered a very promising company, still not much talked about and which, I think, has found the key to getting us out of the energy impasse.

I have seen a lot of projects come and go, but there is something unique about this one. A clear vision, finely articulated, a simple and indisputable technical solution, with the team to make it happen. The concept will be copied, and all the better for the planet!

In this article, I shall attempt to justify as clearly as possible the ambitious assertion stated in the title, which is based in part on the innovative concept of this company.

Though a little long, this article is very didactic, broken down into clear parts, and summarized in 5 points right below.

Feel free share your comments, criticisms, or questions with me at thomasjestin@yelda.ai !

Many people believe that if we want to limit the damage, we urgently need to reduce our consumption of hydrocarbons. In any case, hydrocarbons will no longer be as abundant as they have been in the past. The global peak in conventional oil production was reached in 2008, for example.

Given the difficulties of mass deployment of renewable energies and nuclear power, and the problem of intermittency for non-dispatchable renewable energies, if we listen to degrowthers, in the 21st century, we will only be able to choose between poverty or sobriety.

This line of reasoning is no longer valid: we have enough hindsight (quite a few years now) on certain fundamental trends to be able to say that it contains major flaws regarding the post-2050 period, which we will address in this article.

In Brief:

1. The price of photovoltaic (PV) solar energy has fallen almost continuously since 1970. (link)

2. At the current rate, before 2040, it will be cheaper to produce carbon-neutral synthetic hydrocarbons using ambient air and solar PV than to extract them from the ground in most cases. (link)

3. There are enough raw materials and sunny surfaces in the world to build and install enough solar plants capable of generating the equivalent in gas of our current fossil fuel consumption every year. (link)

4. We could reach critical size before 2040 at the current rate of panel deployment: the total installed base currently doubling every 2 years (link)

5. And that's not counting the progress in fusion energy. Some don't envision commercial operation before 2100, but leading companies are planning on it before 2030. (link)

Humanity took up a similar challenge over 100 years ago! (link)

The conclusion is that abundant green and dispatchable energy is in sight before 2050, which would enable us to reduce global net CO2 emissions to almost zero by then, as per the target set by the IPCC for CO2 in 2050, in order to limit the rise in global warming to the famous 1.5°C.

Economic incentives are there to achieve that transformation, but in the meantime every effort to reduce consumption as well as additional investment in other decarbonized energies are more than welcome in order to limit the damage even further between now and 2050.

Let’s dive in.

1. Solar photovoltaic energy costs plummet

One way of quantifying the energy produced or consumed is to use the unit MWh, for Megawatt-hour. 1 MWh is equal to 1,000 kWh (kilowatt-hour).

For context, a typical European household consumes on average 350 kWh per month, and the average cost of electricity in 2022 was $0.2/kWh, representing an average bill of $70 per month.

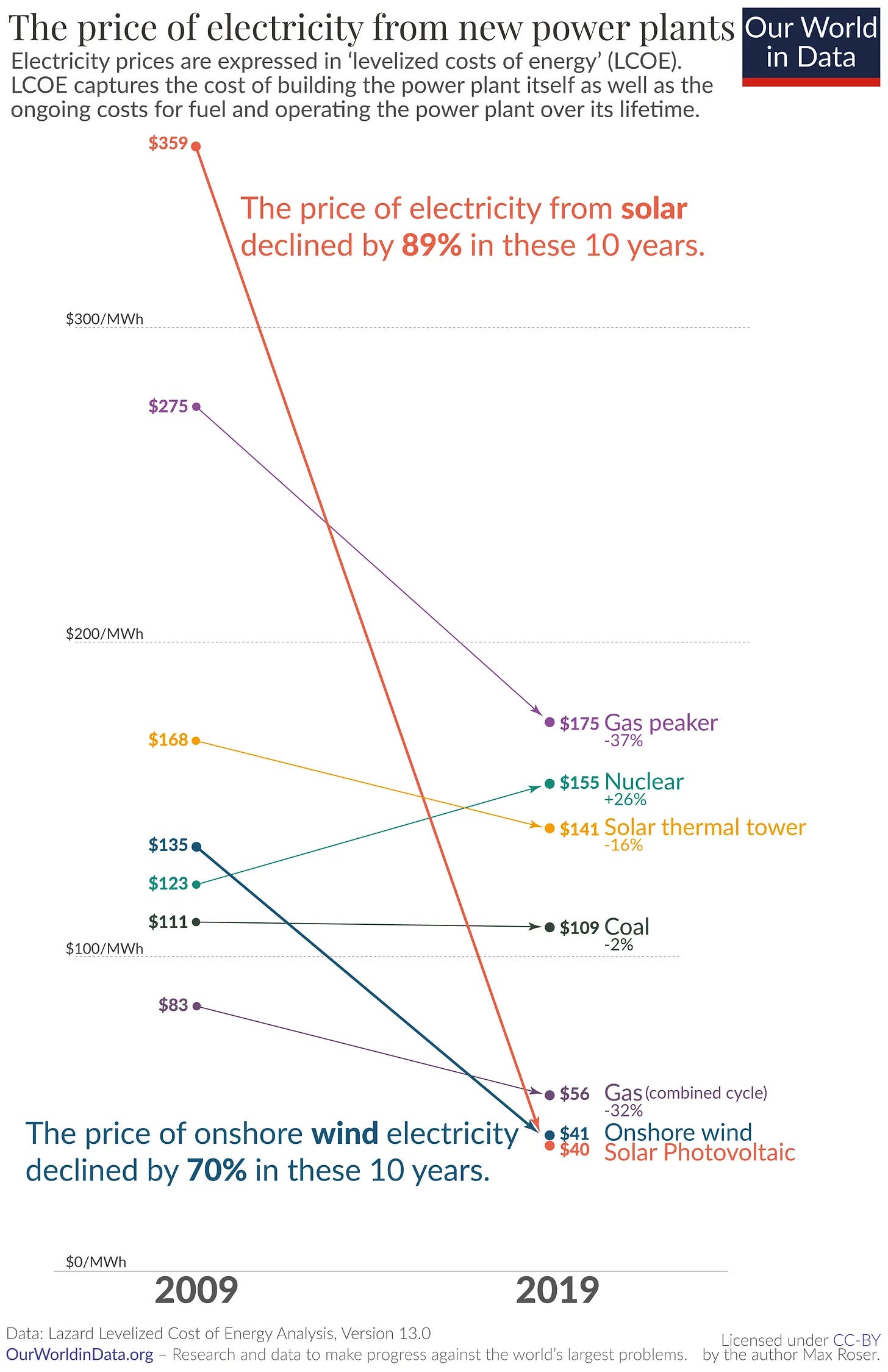

Look at the graph below, which shows the evolution of the cost of producing 1 MWh from different sources from 2009 to 2019.

Notice the orange curve for solar PV electricity has declined by 89% over the 10 years to become the least expensive option!

The term "LCOE" stands for "Levelized Cost Of Energy", which takes the initial cost of building an infrastructure and adds it to the operating and maintenance costs (including financial costs and rent) over its lifetime, and divides this total by the total quantity of energy produced, to arrive at a complete cost per unit of energy produced.

By default, this cost does not consider the intermittency of certain energies, but we will explain below why this is not a problem for the synthesis of carbon-neutral hydrocarbons.

In 2019, the LCOE of solar PV stood at US$40 per MWh, or $0.04 per kWh (kiloWatt-hour).

This spectacular fall discredits the International Energy Agency's (IEA) 2010 forecast for that decade, as we see in the chart below.

In 2010, the IEA forecasted that by 2019 solar PV would cost around $0.23/kWh, almost 6 times more than the actual cost of $0.04/kWh, as seen above!

At the rate at which the IEA predicted these costs falling in 2010, we would have had to wait another 100 years to reach today’s prices.

Even energy expert Ramez Naam, who was very bullish on solar PV, got it wrong. In 2011, he predicted that we would be looking at around $0.14/kWh in 2019, 3.5 times higher than the reality.

And it goes on: in April 2020, a construction site in the United Arab Emirates received an offer from an operator at $0.0135/kWh "LCOE", we are talking about 1.35 cents per kWh!

A year later, in April 2021, another project in Saudi Arabia announced they would "sell electricity at a world record price of $0.0104/kWh".

Do you see the direction the story is taking?

But why have solar PV prices fallen so sharply?

This is due to technical progress, innovations and economies of scale achieved as the quantity of solar panels produced each year has increased! A virtuous cycle has been set in motion: the lower their manufacturing cost, the more we install, and the more we install, the more we invest in research and the more we learn to efficiently produce them, and the lower their manufacturing cost, and so on.

Solar panels lend themselves to Wright's Law, an empirical law that describes the tendency of mass-produced products, as far as demand is not saturated, to see their cost fall by a roughly constant percentage every time total cumulative production doubles, due to innovation, competition, and economies of scale.

We know the name of this law for microprocessors as Moore's Law; and there is also a name for it for solar panels: Swanson's Law.

From 1970 to 2020, the cost of a solar panel has been divided by 500, from $100/watt to $0.2/watt. This price drop is in fact unique in the history of physical infrastructure deployment, according to Ramez Naam.

See below the evolution of the price of a solar panel (in $/watt) from 1976 to 2019 as the years went by and the total installed capacity expanded. Prices fell by 99.6% over this period!

We can calculate that the price fell by an average of 20% for each doubling of the total installed capacity over this period.

The International Renewable Energy Agency (IRENA) has calculated that for each doubling of the total installed capacity, the price of solar PV energy produced - the "Levelized Cost Of Energy" - falls by 38%.

The result has been an explosion in installations and production year after year.

See below the evolution of global solar PV power generation from 1980 to 2021.

Total cumulative installed capacity worldwide is also growing exponentially, in the sense that it is doubling at regular intervals. What's more, the time interval is getting shorter! It took 4 years to double in 2015, 3 years to double again in 2018, and less than 2 years to double again in 2023.

It is interesting to look back at the forecasts made by the International Energy Agency (IEA), which were systematically wrong.

Let us look at its year-on-year forecasts of new installed capacity for the coming years (the blue and black lines are rather stagnant).

In red, you can see the actual evolution of new installed capacity each year, and next to it the IEA forecasts (the WEO, World Energy Outlook, is an annual publication by the IEA) which are constantly revised up a notch to match the reality of the moment, but then forecast a flat evolution that is contradicted in the following years!

The 2019 report forecast that less than 125GW of solar panels would be installed in 2021. The red curve of reality stops in 2019, but we now know the actual value installed in 2021: 180GW! The exponential explosion in deployment continues to this day!

Why should solar PV prices continue to fall over the next few years?

This is because rising demand, increasing volumes, and falling prices are self-sustaining, and the resources needed to produce panels are sufficiently abundant (see part 3).

Solar PV is already cheaper than its competitors in some parts of the world, where it is now more cost-effective to install and operate a new field of solar panels than to continue operating an existing coal/gas power plant.

Given the insatiable appetite of our modern economies for energy, and even more so for cheap, clean energy, as costs come down, it will be profitable to produce this renewable energy in more and more places on Earth. Demand can therefore only continue to explode as long as prices continue to fall.

And prices will fall in parallel, as we said, thanks to the economies of scale achieved by ever larger production volumes, investment in R&D, and improvements in panel manufacturing processes and their installation, operation, and maintenance.

Take the example of the company Erthos which is revolutionizing the sector in the United States with the concept of laying panels on the ground, where until now they were laid in an inclined position attached to steel structures, either fixed or with the possibility to move to follow the sun. With their system, Erthos can certainly capture less energy per panel, but it can lay out in total many more panels within a given perimeter, here's the list of advantages:

Solar panels without the steel structure, saving 35 tons of steel per MW of installed panels!

A field of flat solar panels can be installed 4 times faster than what was the norm until now

70% less cables usage

70% less trenching

70% less water usage

Much more resistant to tornadoes thanks to its lower wind surface area

Cheaper, automated maintenance with cleaning robots capable of rolling over panels laid horizontally on the ground

Up to 2 times more energy produced per unit area vs. previous state-of-the-art technology, because more panels are installed within a given perimeter: 9,310m2 needed to install 1MW of power, compared with between 20,000 and 40,000m2 for the norm until now

With these innovations, the CEO of Erthos explained at the end of August 2023 that they are now able to offer a "Levelized Cost Of Energy" for projects in the southern USA of $25-26/MWh, while competitors' market prices are around $31-32. And this price will of course continue to fall as the manufacturing costs for panels continues to fall.

Will prices continue to fall indefinitely?

No, of course not, but, all we really need is for them to fall for a few more years at the current rate, and we will be able to produce gas and other carbon-neutral synthetic hydrocarbons at a price that is initially competitive, and then rapidly lower than the market price, virtually everywhere on Earth. This will enable the explosion in installations to continue until demand is saturated and fossil fuels use is virtually eliminated! Once this level has been reached, estimated at $10/MWh, solar PV prices can continue to fall, but this will not even be necessary to eclipse hydrocarbons extracted from the ground, i.e. fossil fuels.

We will develop this last point in the next section.

2. It will be more profitable to manufacture hydrocarbons than to extract them from the ground, almost everywhere, before the year 2040

In January 2023, the startup Terraform Industries, founded by a former engineer from NASA's prestigious Jet Propulsion Laboratory (JPL), published an edifying white paper that explains in detail how it will soon be possible to use PV solar energy to convert atmospheric air into methane (natural gas) at competitive prices. We're talking about e-methane or electro-methane.

A synthesis gas of this kind has the advantage of being carbon-neutral: we take carbon from the atmosphere to synthesize it, and we emit the same amount when we burn it, so the balance is zero - we haven't added any CO2 to the atmosphere in net terms. What's more, as some of this gas can be used to produce durable plastic objects, it will sequester carbon that will not be returning to the atmosphere any time soon, so we can even talk about negative emissions.

The concept is quite simple: use PV solar energy to capture water and CO2 from the atmosphere, separate the water into hydrogen H2 and oxygen O2, and combine hydrogen and CO2 to produce methane (CH4) ready for injection into a pipeline, without the need for intermediate compression.

These are precisely the techniques being considered to produce methane and oxygen on Mars from elements present on the Red Planet, methane and oxygen being the fuel pair used by SpaceX's Starship rocket under development! It's no coincidence that the founder of Terraform Industries used to work on Mars rovers for NASA!

The French transporter CMA-CGM, for example, has decided to focus its energy transition on liquefied natural gas (LNG). By the end of 2024, it will have 44 LNG-powered e-methane-compatible ships, already representing over 7% of its total fleet, including its largest vessel, the "Jacques Saadé" (named after the founder of CMA CGM), which entered operation in 2020 and is the 10th largest container ship in the world.

It is also possible to generate other hydrocarbons from methane, such as kerosene for aircraft, or methanol to which the shipping company Maersk is switching. This technique will enable us to beat all fossil fuels on price in the long term! The question remains whether it can be deployed fast enough, and on what scale, which we will see in the next few sections.

Their system even generates excess liquid water from the atmosphere, even in desert areas.

The beauty and simplicity of their approach is not to seek to perfect the most efficient machines available for these processes, but the cheapest machines possible, banking on the continuous fall in solar PV energy to at least $0.01/kWh (we're at $0.025/kWh today in the southern USA).

A passage from their white paper illustrates their philosophy perfectly:

"The machines are simple. They use standard commodity materials and parts available almost anywhere on Earth. Their manufacture is simple and requires no precision tooling, exquisite training, or particularly hazardous materials."

"There is a tradeoff between efficiency and complexity/cost. But electrical efficiency matters less than capital efficiency when it comes to rapid scaling. Why is that? The Terraform Industries natural gas production system has many factors of production: labor, materials, electricity. Only one of these is getting cheaper. Cheaper, lower electrical efficiency machines capture the upside of cheaper electricity. "

"We do not intend to waste much effort attempting to discover processes obscure enough to be patentable and yet useful enough that they could somehow help us scale faster. The tools are at our disposal. The patents expired 50 years ago. This process is not particularly difficult, it's just been historically unprofitable because electricity wasn't cheap enough back then. It is now.

Their machine, whose details were unveiled in June, converts electricity at $0.01/kWh into carbon-neutral natural gas (methane) at a price of less than €0.5/m3 (less than $15/kcf or thousand cubic feet).

It is designed to fit neatly into a container. Production starts Q2 2024.

For context, in December 2022, gas prices in France were between €1 and €3 per m3, depending on the criteria used.

Their machine doesn't need to be connected to a power grid; coupled to a field of solar panels, it uses the electricity produced directly to generate methane.

But when on earth will we get to $0.01/kWh for solar PV? That, of course, will depend on where in the world we are, and the cost of solar panels. Based on the current rate of decline in panel costs, the most favorable locations will be able to produce competitive synthetic methane as early as 2024, intermediate locations by 2032 and the least propitious markets before 2040. This may take longer, but it doesn't change the outcome – it is inevitable. In fact, thanks to subsidies in the United States under the Inflation Reduction Act, coupled with the war in Ukraine, it is already profitable in the south-western United States!

Indeed, their Terraform Mark 1 costs $100k, is autonomous with minimal maintenance, and lasts 5 years. It must be associated with a field of solar panels with a total power of 1MW, costing around $1 million and lasting 30 years, i.e., an amortization of $166k over 5 years. This gives a total cost of $266k over 5 years. It will generate 2,300 MCF per year (thousands of cubic feet), with a selling price of $10/MCF and subsidies of $54/MCF, making 2300*5*64=736k$ in revenue over 5 years.

Given the price of gas in Europe, if they installed machines there today, and if there were enough solar panels in place, even at today's prices, then they would already be cheaper than the gas Europe imports!

Finding this essay interesting? Share it on Whatsapp, just click here ❤️

If yes, feel free to take 3 seconds to forward that newsletter to one person, or share it on Whatsapp clicking here, I'd be immensely grateful 🙂

If that email was forwarded to you, you can click here to subscribe and make sure to receive future editions in your mailbox (many CEOs and startup founders are subscribers)

But what about methane leaks?

One criticism is that while the combustion of methane synthesized by PV solar energy is carbon-neutral for the atmosphere, its production, distribution, storage, and use generate leakage here and there along the way, which is serious because methane has a global warming power (GWP) 30 times greater than that of CO2 over 100 years, and even more in the short term. There are four answers to this:

First, we need to understand that the world is not about to stop using methane for very long, given i. the difficulty of decarbonizing certain energy-intensive activities, ii. the problem of the intermittency of renewable energies, and iii. the economic development aspirations of the world's countries, which are far from having the GDP/capita of Europe or the United States (the nominal GDP/capita of China and India are respectively 16% and 3% that of the US). So, by default, these leaks will continue to occur for decades to come, and worst case scenario, all we will be doing is replacing them.

Secondly, many of today's leaks occur at fossil gas production sites, where extraction machines are in contact with the ground and its depths, environments that are never exactly the same and difficult to control perfectly. In Terraform Industries' case, on the other hand, everything is standardized, so leaks are easier to eliminate.

And falling prices for satellite imagery coupled with advances in AI are already enabling methane leaks to be detected much more quickly and systematically than before, and this can only get better. As these leaks are a loss of money, if they become cheaper and cheaper to detect, operators will have a natural incentive to repair them. Advances in valve technology will also help solve this problem.

In the medium term, Terraform Industries also plans to use their machines to capture methane gas from the atmosphere and convert it into CO2, which has a much lower greenhouse effect and is used as an ingredient in their process.

Why not stick to green hydrogen? Why not focus on the hydrogen economy?

We said that hydrogen production was one of the intermediate stages, but why not stop there? After all, it would be green hydrogen at a competitive price!

It is possible, but hydrogen is much more difficult and costly to store and transport than methane. Methane is 10 times denser at room temperature than gaseous hydrogen. In other words, one ton of hydrogen is 10 times the volume of one ton of methane. Methane liquefies at -160°C, compared with -253°C for hydrogen, and liquid methane remains 6 times denser than liquid hydrogen. Hydrogen H2 is a very small compound, which seeps into everything and leaks very easily. CMA-CGM has explored this question for its ships, but explains that hydrogen can only be stored for 16 days due to leaks and the very low temperature required, compared with over 90 days for a ship running on liquefied natural gas/e-methane.

Hydrogen is also highly unstable and dangerous, with a high risk of explosion when in contact with oxygen in confined spaces, and in much lower concentrations than hydrocarbons. The risks of accidents are therefore very high, and if we were to bet everything on the "hydrogen economy", a catastrophe would inevitably occur, which would certainly put a stop to such a transition.

Since future cost reductions in solar PV energy will also make it possible to produce competitive methane, we might as well do so, since it is much easier to store and transport, demand is much greater, and the infrastructure already exists, unlike hydrogen, where everything still remains to be done!

And why not make green, carbon-free ammonia instead?

Others are proposing to use renewable energies and ambient air to produce ammonia, a molecule composed of hydrogen and nitrogen (NH3), for use as a carbon-free fuel. But the technology for producing green ammonia is not yet mature, and neither is that for ammonia engines. In addition, its combustion generates emissions of nitrogen oxides (NOx), which have a strong greenhouse effect. One of these, nitrous oxide, has a global warming potential over 100 years that is 310 times greater than an equivalent mass of CO2. This could eventually be resolved with catalytic converters, but the need for platinum and other rare metals on a large scale further complicates the equation. In the event of a leak, ammonia is highly toxic to humans. It is less dense than hydrocarbons, combustion is difficult to start and requires the use of other fuels.

In short, many handicaps which convinced Lucie Nurdin, a PhD in chemistry from the University of Calgary and a graduate of Normale Sup' (France’s most selective science “grande ecole”), to join Terraform Industries. Lucie Nurdin knows the subject well, having done her post-doctoral studies at Caltech (California Institute of Technology) specifically on hydrogen-based and nitrogen-based carbon-free fuels. She confided in me that ammonia could be a solution, but it will take 50 years; we don't have the time. Terraform Industries, with its carbon-neutral synthetic methane, will be able to make a large-scale impact much sooner, she told me.

3. There are enough raw materials and sunlit areas in the world to build and install solar plants capable of generating the synthetic gas equivalent to our current fossil fuel consumption every year.

Let's start with total annual world hydrocarbon consumption in 2022, which we can round off to 140,000 TWh, i.e. 140 million GWh.

Let us run a thought experiment, let’s suppose we produce all these hydrocarbons in the form of synthetic gas using solar PV electricity and Terraform Industries' machines and let us see if it is possible.

Experimentally, the efficiency of converting electrical energy into gas is around 30%, so it takes 3.33 units of electrical energy to obtain one unit of energy in the form of gas.

We will therefore need to produce 420 million GWh of solar PV energy per year to generate the equivalent of all the fossil fuels we consumed worldwide in 2022.

By the way, while making hydrocarbons cheaper will raise demand for it in some industries hard to decarbonize, some of the demand will also fall over time due to the electrification of land transport, heating (heat pumps) and cooking hobs, among other things.

In fact, once electrified, these activities will require less energy for the same result:

An electric car converts almost 90% of the energy it consumes into motion, compared with 20% for a combustion-powered car: for the same energy, an electric car will go more than four times farther!

Some heat pump models boast efficiencies of 400% or more, meaning that 4 kWh of heat can be created in a home for every 1 kWh of electricity consumed by the pump. Modern gas boilers do 90% at best and cannot exceed 100% due to the laws of physics.

So, even if all the additional primary energy for this electrification is produced by burning hydrocarbons, it will take much less than is burned today for this purpose in thermal vehicles and heating and cooking systems.

The primary energy savings achieved by electrification will then offset some of the future rise in energy requirements linked to the expansion of air and sea traffic in particular. There's plenty of room for improvement, given that road transport currently emits 4 times more C02 than air and sea transport combined.

In our scenario, there's no need for batteries, no need to connect the new solar plant to the grid

In our scenario, since all the solar PV energy generated will be used directly on site to produce carbon-neutral synthetic gas, there is no need to worry about copper or the time required to connect the solar plant to the grid. There is no need to worry about intermittency, and no need for batteries.

The only question is whether and when it will be possible to produce all the solar PV energy needed to synthesize the equivalent of today's fossil fuels every year.

Let us start with the question of what surface area is required

Let us start with the Erthos technology detailed above, which assumes 9,310m2 for 1MW of power. We will assume that it operates only 6 hours a day, to be conservative, and 80% of the days in the year. This is conservative because we would locate these panel fields in arid zones where there are few clouds. These 9,310 m2 would therefore generate 1MW*6h/day*365days*80%=1,752 MWh of electricity per year, or 1.75 GWh.

We need 420 million GWh per year, so simple cross multiplication shows us that we'll need 420 million*9,310/1.75=2,235,000 million m2, i.e. 2.2 million km2.

It could be argued that we have not included the surface area occupied by Terraform Industries' machines, which come on top of the solar panel fields. In fact, by default, such a field already provides space for machines, the inverters, which transform the direct current produced by the panels into alternating current to be sent to a power grid. But here, the electricity is not sent back to a grid, there is no connection to a grid, no need for inverters - the electricity is used on site to produce methane! This space reserved for inverters is then easily used for the Terraform Industries machines, which only need 75m2 of the 9,300m2 occupied by a field of solar panels with an installed power of 1MW, i.e. 0.8% of the surface area, bearing in mind that in fact only 92% of the surface area of an installation is covered by solar panels with Erthos, there is ample space!

This surface area, 2.2 million km2, represents 1.4% of the Earth's land surface. Australian deserts occupy 2.7 million km2; therefore, we would need 80%. Of course, we would not be putting it all in Australia; we could also install infrastructures in the Sahara (which covers 9.2 million km2), and in other arid regions of the world, in Saudi Arabia, China, etc. In fact, the United States has enough room to meet its own current hydrocarbon needs. And after a few more years of solar panel prices falling, we will also end up with sufficiently low solar PV energy even in areas where there is less sunshine than these arid zones.

In short, space is not a limiting factor. When PV solar energy makes it possible to produce synthetic gas at a fraction of the cost of fossil fuels extracted from the ground, there will be enough space on Earth without any expansion problem, to the point of replacing all fossil fuels!

What about the raw materials needed for the solar PV panels?

We had arrived above at 9,310m2 for 1MW of installed power, or 9,310km2 for 1,000GW. Therefore, with 2.2 million km2 we have 2.2 million*1,000/9,310=236,000 GW of total installed power.

An installation with an installed capacity of 1MW requires 3,000 panels of 350 watts each. That is 3 million panels for 1GW. We will need 236,000 *3 million = 708 billion 350-watt panels.

Moreover, a standard 350-watt solar panel weighs 21kg, of which 76% is glass, 10% plastic polymer, 8% aluminum, 5% silicon, 1% copper and less than 0.1% silver and other metals.

But that's the situation today! One of the reasons why the cost of panels will fall is that we will be able to produce them with less material, so material requirements per watt of installed power can only go down!

To date, glass has been the most needed component; and to make it, we need sand and limestone, which are in plentiful supply. It also requires a lot of energy, which we will talk about in the next section. But guess what? We already know how to make solar panels without glass! That's what the Bila Solar company is doing: 350 watts at 6.4kg, more than three times lighter than today's standard, and with the same lifespan!

The material often singled out is copper. For our solar panel park to produce the solar PV energy needed to produce all the hydrocarbons consumed in 2022, we'll need 708 billion*21kg*1%=148.7 million tons of copper, say 150 million.

Worldwide copper reserves are currently estimated at 870 million tons, and copper resources at 5,000 million tons. Reserves are deposits that have been discovered, evaluated, and deemed profitable. Resources are much larger, and include reserves, potentially profitable discovered deposits and undiscovered deposits predicted based on preliminary geological studies. Copper occurs naturally in the earth's crust. To give you an idea, in the year 2000, reserves were estimated at less than 350 million tons.

For the material considered the most problematic, 17% of reserves estimated to date will be required, and 3% of resources.

Finally, it is not often talked about, but aluminum can be substituted for copper:

Aluminum has 60% of the conductivity of copper, so you need 25% thicker wire for the same results. However, the aluminum in this equivalent wire will cost and weigh about half as much as copper would.

Aluminum is 1,200 times more abundant than copper.

What about silver? It would amount to 15 million tons, quite a lot. Well, it will be substituted. We’re using it for now as it’s still affordable and available enough, but when prices will go up, we’ll use something else. There are many ideas already. "Technologies that use cheaper metals are now sufficiently advanced, and will soon be put into mass production once silver prices surge”, according to Zhong Baoshen, chairman of Longi Green Energy Technology Co. — the world’s biggest panel manufacturer. Manufacturers are talking of using copper and aluminum.

Silicon is ultra-abundant, making up over 27% of the earth's crust, is found in sand and quartz, and is not limiting.

In short, copper, and other raw materials won't be the limiting factor either!

What are the material requirements for Terraform Industries' machinery?

We've just looked at the solar panels, now let's take a look at the Terraform Industries machines required, such as the Terraformer Mark One. A total installed capacity of 236,000 GW, or 236 million MW, will be associated with 236 million of these machines requiring a power of 1 MW. This machine will be comparable in mass to an automobile, says Terraform Industries (but much less complex), say 2 tons to be generous. All in all, 500 million tons of mass will be needed, which can be recycled. Their Mark One machine uses no rare metals, a design imperative for the company. Just a little nickel, very little copper and only for the cables.

The company predicts that building 60 million of them a year will be sufficient, to be on the safe side. That's 120 million tons of mass per year. Assuming it's mainly steel, there'll be no problem: steel production was close to 2 billion tons in 2022 and is largely scalable, being based on iron, one of the most abundant elements in the earth's crust.

As for nickel, each machine requires 25kg. In all, 236 million machines will be needed, so that's about 6 million tons of nickel, or less than 7% of the world's nickel reserves of 94 million tons.

The construction of these machines will not be a limiting factor.

What about the energy needed to produce the panels?

It is estimated that it takes 200 kWh of energy today to produce a 100-watt panel.

Let us assume that energy is needed in the form of gas, and that we are talking about a standard panel. This is very pessimistic, as we have seen that solar panels already exist that are 3 times lighter than the norm for the same wattage, and do not require glass, which takes a lot of energy to produce.

Assuming that a 100-watt panel operates 6 hours a day, 80% of the days of the year, for 25 years, it will produce 100*6*365*0.8*25=4.38MWh of solar electric energy, which, with 30% energy efficiency in conversion with Terraform Industries machines, gives 1,300 kWh of energy in the form of a gas.

This means you need to invest a maximum of 200 kWh in energy up front, and then obtain 1,300 kWh over 25 years - an energy investment that more than pays for itself. Deployment will take some time, as we will see in the next section, but the need for energy cannot stop it!

4. At the current rate of panel deployment, with the total installed base doubling every 2 years, we'll reach critical size before 2040.

We saw in Part 2 that the approach is already cost-effective in some places and will soon be almost everywhere, providing the incentives and financial fuel for an exponential explosion in installations, even if the cost of solar panels stops falling after that.

In part 3, we saw that neither space, raw materials, nor energy can prevent the inevitable replacement of fossil fuels by synthetic hydrocarbons.

But there is still the question of the timetable: how long will it take to reach 236,000 GW of total installed capacity?

By the end of 2023, the world's total installed capacity will be around 1,600 GW. We saw earlier that by the end of 2023, it will have taken less than 2 years for this total installed base to double. In fact, the time taken to double has been decreasing from one doubling to the next for some time now.

Let us assume that the time taken to double stops decreasing and even slows down a little to stabilize at every 2 years.

This gives:

2025: 3,200 GW

2027: 6,400 GW

2029: 12,800 GW

2031: 25,600 GW

2033: 51,200 GW

2035: 102,400 GW

2037: 204,800 GW

2039: 409,600 GW

We're talking about a titanic undertaking here, without a shadow of a doubt, the solar panel industry is going to explode and become central to the economy, but there is nothing impossible about it - on the contrary, profitability, space and raw materials make it entirely possible. This revolution may be postponed or delayed by a few years, but it is inevitable, unstoppable, and already underway.

By the end of 2040, we should be able to synthesize, in a carbon-neutral way and at a lower cost than today, the equivalent of the amount of fossil energy consumed worldwide in 2022.

5. Commercial nuclear fusion not for 2100

Some say commercial fusion won't happen before 2100 because of the slow progress of ITER, the international nuclear fusion research and engineering megaproject aimed at creating energy through a fusion process similar to that of the Sun.

But in the private sector, the ecosystem is booming, with over 40 companies in the sector as reported by The Economist, and there are now serious reasons to bring this date forward drastically.

Because nuclear power has long been synonymous with pharaonic projects requiring state intervention, many believe that this cannot change.

But the same was said of space. If we remember correctly, it was said that only a few countries could design and build rockets, and no one would ever be able to land a rocket back on Earth…

Until Elon Musk came along and shattered these preconceived notions. And he has now inspired many in other fields long considered the prerogative of nations.

The example of Commonwealth Fusion Systems

Take Commonwealth Fusion Systems (CFS), for example, which has raised $2 billion and is aiming for the first positive-energy reaction by 2025, with rapid commercial deployment from 2030.

2030!

Here is a summary of an interview with the founder of CFS, entitled "Can we replace every coal plant by 2040?":

Recent innovations in materials science have made it possible to develop superconductors which can then be used to make magnets far more powerful than was previously known: "a complete step change in the 300-year history of magnets".

The fusion research community told them: "If you had that magnet, that machine would work, and it would be that small. We don't see any showstoppers except that magnet".

They have succeeded in creating a magnet twice as powerful as what was until now state-of-the-art.

CFS is using it to build a much smaller fusion device than ITER, which does not use these innovations: it fits in a garage, compared with a stadium-sized building for ITER, which is the biggest construction project in Europe.

In fact, CFS has done in 3 years what took ITER 25 years in magnet technology.

ITER is aiming for the first positive-energy reaction by 2035, while CFS is targeting 2025. The goal is to do at least Q >1, a bit more energy out than total energy in, they’ll do Q=11!

Deployment will then start in 2030 and could go very quickly. As CFS has a compact system and uses fusion to heat water, it will not necessarily need to rebuild power plants from scratch, and they will be able to convert coal- and gas-fired plants around the world.

In April, United States authorities decided that fusion would be much less regulated than nuclear fission, as it presents far fewer risks. Deployment will be much easier politically, and therefore faster and cheaper.

The Helion example

Let us also look at a second actor, Helion.

Helion raised $500 million by 2021, including $375 million invested by Sam Altman, none other than the CEO of OpenAI. Prior to that he was CEO of Y Combinator, the highly regarded incubator behind such successes as Airbnb, Dropbox and Stripe.

This is his biggest-ever investment in a start-up. He wrote in July 2022: "Helion has been progressing even faster than I expected and is on pace in 2024 to 1) demonstrate Q > 1 fusion (fusion with more useful energy out than in) and 2) resolve all questions needed to design a mass-producible fusion generator."

"The goals of the company are quite ambitious- clean, continuous energy for 1 cent per kilowatt-hour, and the ability to manufacture enough power plants to satisfy the current electrical demand of earth in a ten-year period."

Sam Altman had initially invested $10 million in Helion, but then boosted his investment considerably, very confident that it is going to work.

Eventually, Helion plans to build power plants the size of a large container (15m2), capable of generating 100MW of electricity. By comparison, solar panels would require 931,000 m2, 62,000 times more space.

In May 2023, Helion announced a power purchase agreement with software giant Microsoft. Helion will commission its first power plant in 2028, reaching full production capacity of at least 50 MW less than a year later.

"This is a binding agreement that carries financial penalties if we fail to build a fusion system," said David Kirtley, founder and CEO of Helion. "We are committed to being able to build a system and sell it commercially to Microsoft."

Helion has developed and tested six prototypes to date. The company announced in 2021 that the latest prototype had reached temperatures over 100 million °C, making it the first private company to publicly reveal that it had reached the temperatures required for commercial operation. Helion is developing a special system known as "pulsed non-ignition fusion ", which has the advantage of requiring fusion only for short periods.

The company is currently building a seventh prototype, Polaris, with operations due to start in 2024. This will be the first time a fusion machine will demonstrate that it can create electricity from fusion with a net energy gain.

Technological advances in computers, electronics and fiber-optic networks now make Helion's approach possible.

Helion intends to use helium-3, but there's no need to go and get it from the moon: it will be produced by fusing deuterium in its fusion generators.

But where to find deuterium? It is simply a form of hydrogen with an extra neutron in its nucleus, present in all forms of water. The Earth's oceans contain enough to produce 10¹⁶ TWh of electricity, enough to meet all humanity's current energy needs for billions of years.

The most advanced companies are talking about the start of deployment as early as 2028 and 2030! There may well be a delay, but that still does not mean we cannot expect anything before 2095!

Humanity took up a similar challenge over 100 years ago!

We will get by with solar through prices, with carbon-neutral energy abundance in sight before 2050, without having to choose between poverty and sobriety from then on! Fusion could also come to the rescue to further accelerate this timetable, though it is not absolutely essential, it’s more than welcome!

In the meantime, however, all the CO2 emissions that cannot be captured and stored - i.e. almost all of them - will continue to spoil the atmosphere and warm the planet further, so it remains urgent to continue investing in other "climate tech" and to advocate sobriety as much as reasonably possible to further limit the damage in the meantime.

In 1898, the man of science Sir William Crookes gave an anthology speech at the British Academy of Sciences before the scientific elite of the day. He issued an uncompromising warning to the audience: our planet would soon run out of natural fertilizer to enable agriculture and provide enough food for mankind. By 1930-1940 at the latest, unless synthetic fertilizers ("chemical manures" he called them) were invented and produced in sufficient quantities, famine would kill hundreds of millions. We now know that he was right about everything: without synthetic fertilizers, "natural" agriculture on Earth can only feed around 4 billion people.

The limiting factor is nitrogen fixed in molecules that are easy for plants to exploit: although our atmosphere is overflowing with nitrogen (78% of its composition), it is inert and not exploitable by plants by default. The natural processes that fix it into exploitable molecules are slow, and that's the problem. Sir William Crookes' warning, coupled with a solemn call for innovation, caused an immediate sensation and spread rapidly throughout the scientific community and beyond.

In 1909, German chemist Fritz Haber succeeded in fixing atmospheric nitrogen in the laboratory. In 1913, just five years later, a BASF research team led by Carl Bosch developed the first industrial application of Haber's work: the Haber-Bosch process. Today, this process produces enough synthetic fertilizer to feed 8 billion Homo sapiens. Without it, there would be half as many souls on Earth today. It is hard to think of an innovation as momentous in the 20th century.

Terraform Industries is going to capitalize on the fall in solar PV energy production costs to popularize a similar technique: fixing CO2 from the atmosphere to produce the hydrocarbons we are going to need, no matter what anyone says, to offer the next generations a world of abundance, and on a very large scale, without warming the planet and while beating fossil fuels on price.

_____________________________________________________

Thanks for reading :)

If you made it until here, well, thanks a lot for reading this essay! A very simple way to encourage me to continue writing is to take a few seconds to:

transfer this piece to at least one curious friend, or share it on Whatsapp clicking here

click on the little star next to that email in your mailbox

click on the heart at the bottom of that email/article

Thank you so much in advance! 🙏

Here to subscribe to make sure you get the future editions if this one was forwarded to you.

More about me

I’m a 2-time digital entrepreneur (Yelda, KRDS), passionate about technology at large, in particular space, AI and climate tech. I’m a tech writer and speaker, here are my latest articles and podcasts. I’m originally from France, living in Singapore since 2013.

Here are my Linkedin and Twitter (make sure to add me on Twitter, one of my followers is Robert Zubrin), or contact me at thomasjestin@yelda.ai.

For the French speakers: this newsletter has a French version with slightly different content: Parlons Futur

Have a great end of week :)

Thomas